Products

Ensuring product quality with OPTIVE's advanced inspection systems

OPTIVE Products

Providing customized inspection solutions for new semiconductor & FPD processes.

Wafer Inspection System

Semiconductor Wafer Inspection System

- Nanometer-level Defect Detection

- High-speed Automated Inspection Process

- AI-based Defect Analysis

Display Inspection

Display Inspection Solution

- OLED/LCD Panel Full Inspection

- Detection of Mura, Spots, Particles

- Real-time Quality Monitoring System

Smart Monitoring

AI-based Smart Monitoring

- Deep Learning Pattern Recognition

- Predictive Maintenance & Anomaly Detection

- Integrated Data Analysis Platform

3D Shape Inspection

3D Shape Inspection System

- Non-contact 3D Shape Measurement

- Nano meter level ultra Precision

- Compatible with Various Patterns

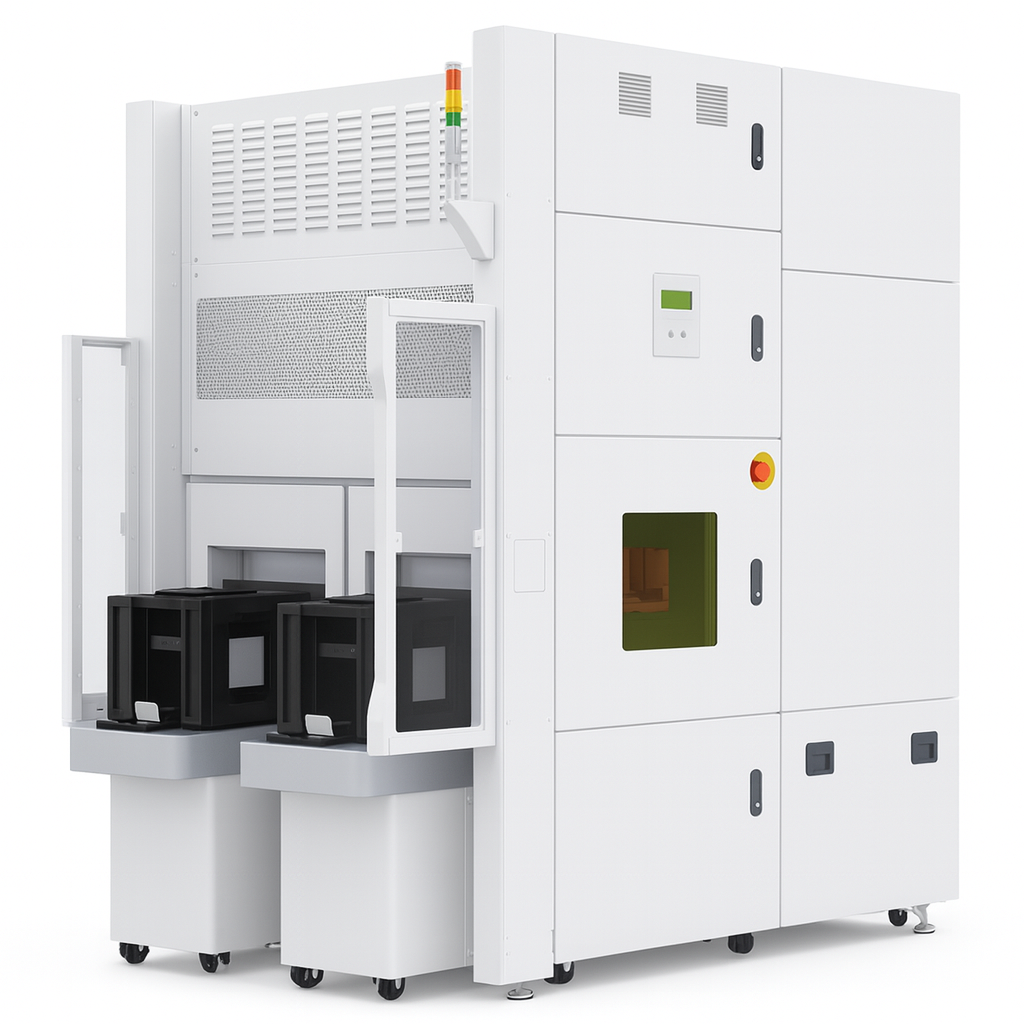

2/3D Complex Inspection SYSTEM

Improving productivity and accuracy simultaneously with an automated defect review system. Accurately detecting even minute defects through high-resolution imaging technology and AI-based analysis.

High-Speed Inspection

Applying large-area 3D optics surpassing existing technologies to maintain fast production speeds required by customers

Precision Analysis

High-precision system capable of detecting nanometer-level defects

AI-Based Classification

Automatic classification and analysis of defect types using machine learning algorithms

Inspection System

Ensuring product quality and minimizing defect rates with advanced inspection systems. Providing various inspection modes and real-time monitoring functions.

Multi-Mode Inspection

Implementing various 2D and 3D inspection/metrology with a single optical system

Real-Time Monitoring

Checking inspection results in real-time and enabling immediate response

Data Analysis

Collecting and analyzing inspection data to utilize for quality improvement